FIN - Inlet range for smart waste collection system

Team work at AHO (Oslo, Norway) for waste management company ENVAC Group in 2017

Originally from Sweden, ENVAC created the vacuum waste technology and run waste collecting systems since 1961. They asked us to work on their already existing waste inlets' design. The goal was to give a strong visual identity to the products family while enhancing the user experience with new functionalities.

We had the chance to visit the Fornebu's facilities, bordering western parts of Oslo. We saw how the waste is manage after being sucked in the pipelines. We saw inhabitants using the actual inlets. We were able to understand the problems in the use.

We have detected no real family identity on the already-existing inlets. All four of them could have been from different companies.

Strong of our research, we drew all the interactions, problems or thoughts. This helped us see the bigger picture.

We looked at the user experience and mapped the emotions attached to it. Thanks to this method, we were able to pin point the problems both in the experience and the design.

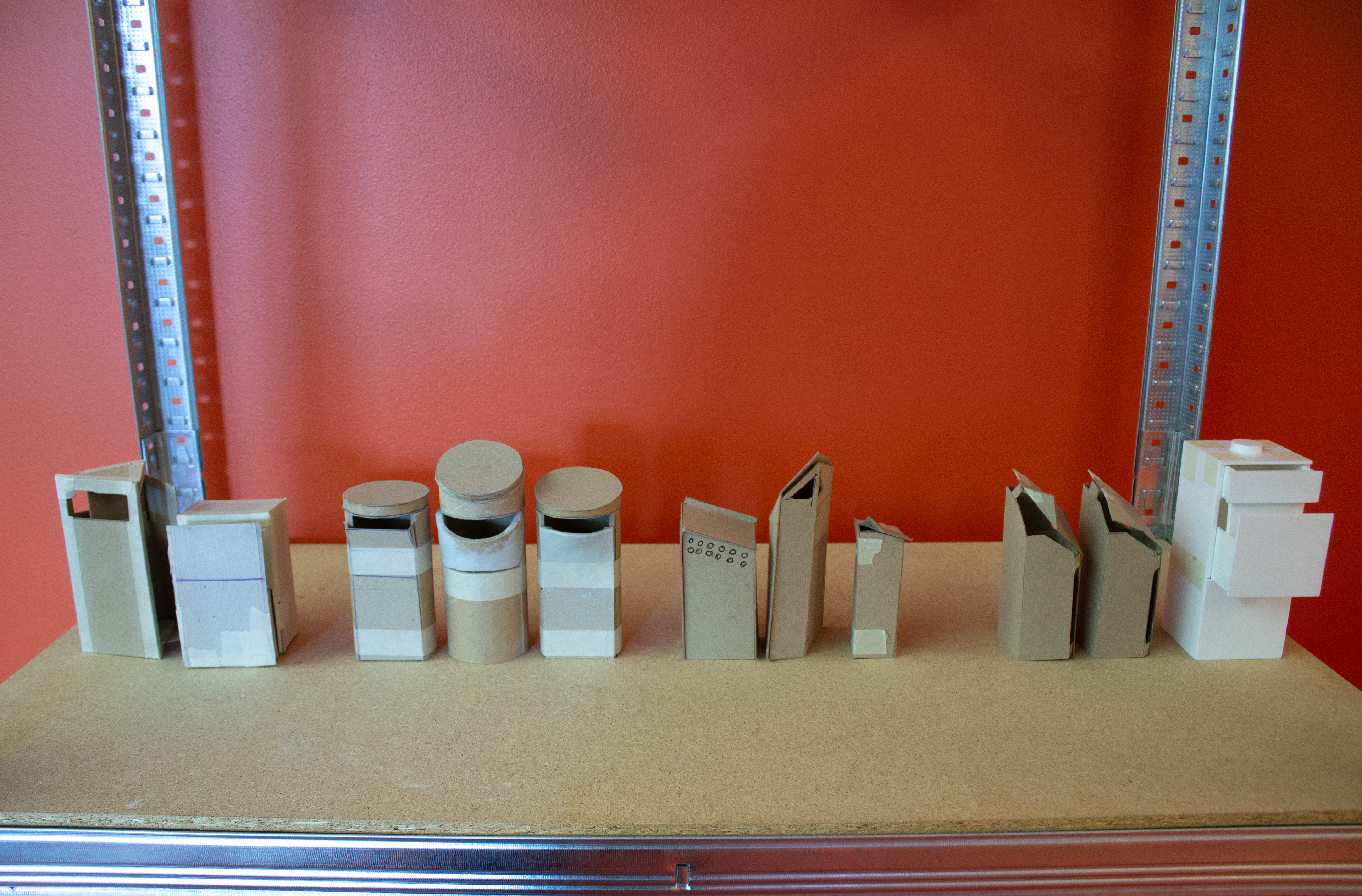

After sketching, we started by making cardboard mockups. At the end of the process, we chose one design and 3D printed a functioning drawer system to verify our ideas.

Since we had to produce a range of different services, we planned three intelligent and purposeful upgrading designs.

We think the customer (here the city councils or commercials areas) should not choose the service for its design, but the service with a design.

The fin create an opening only on the household rubbish fraction. Any passer-by can to throw his waste like any other public bins. We integrated this already existing function in the design.

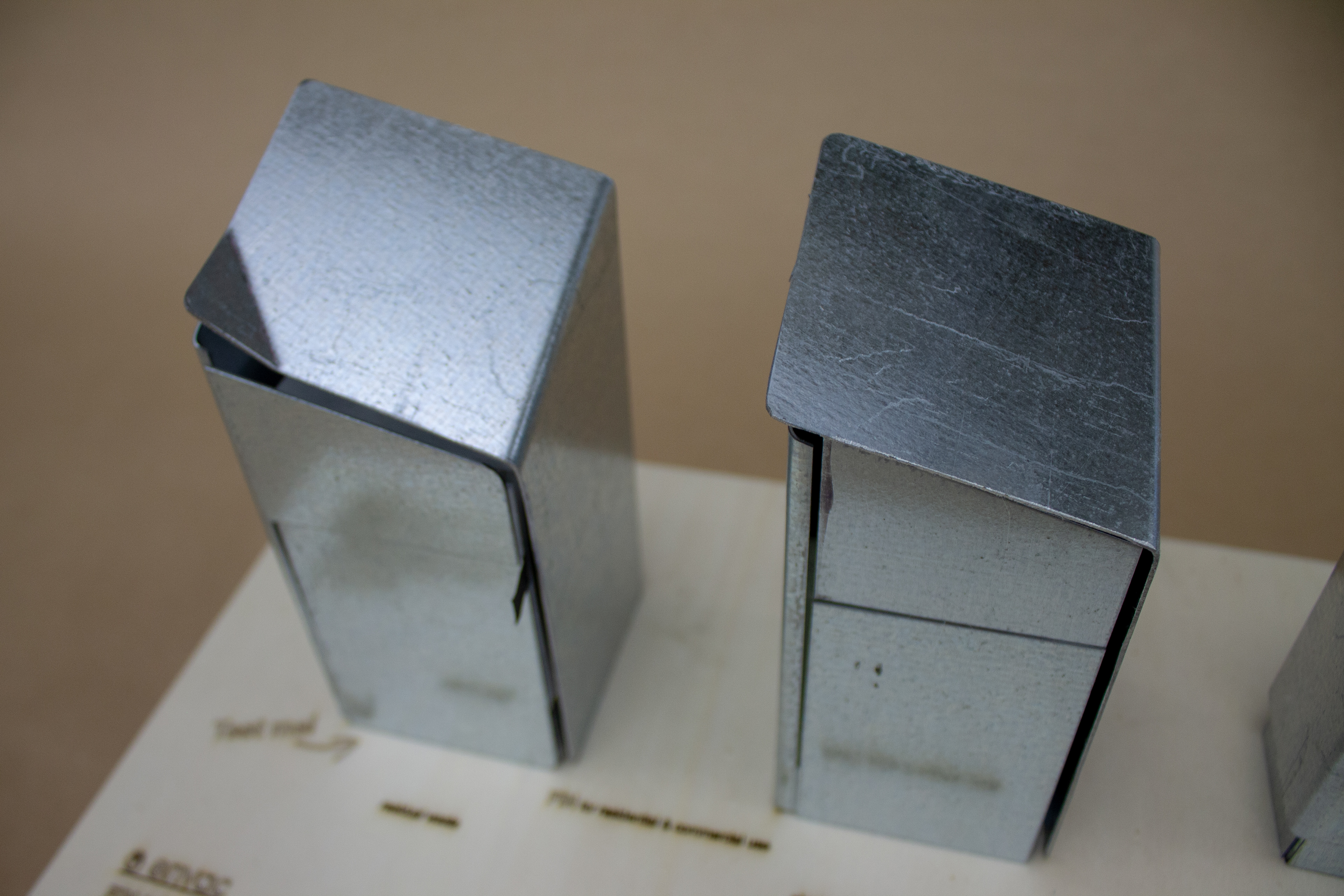

The negative space between the two metal sheets forms the window for the air intake.

We produced an honest and timeless design which integrate the diversity of Scandinavia.

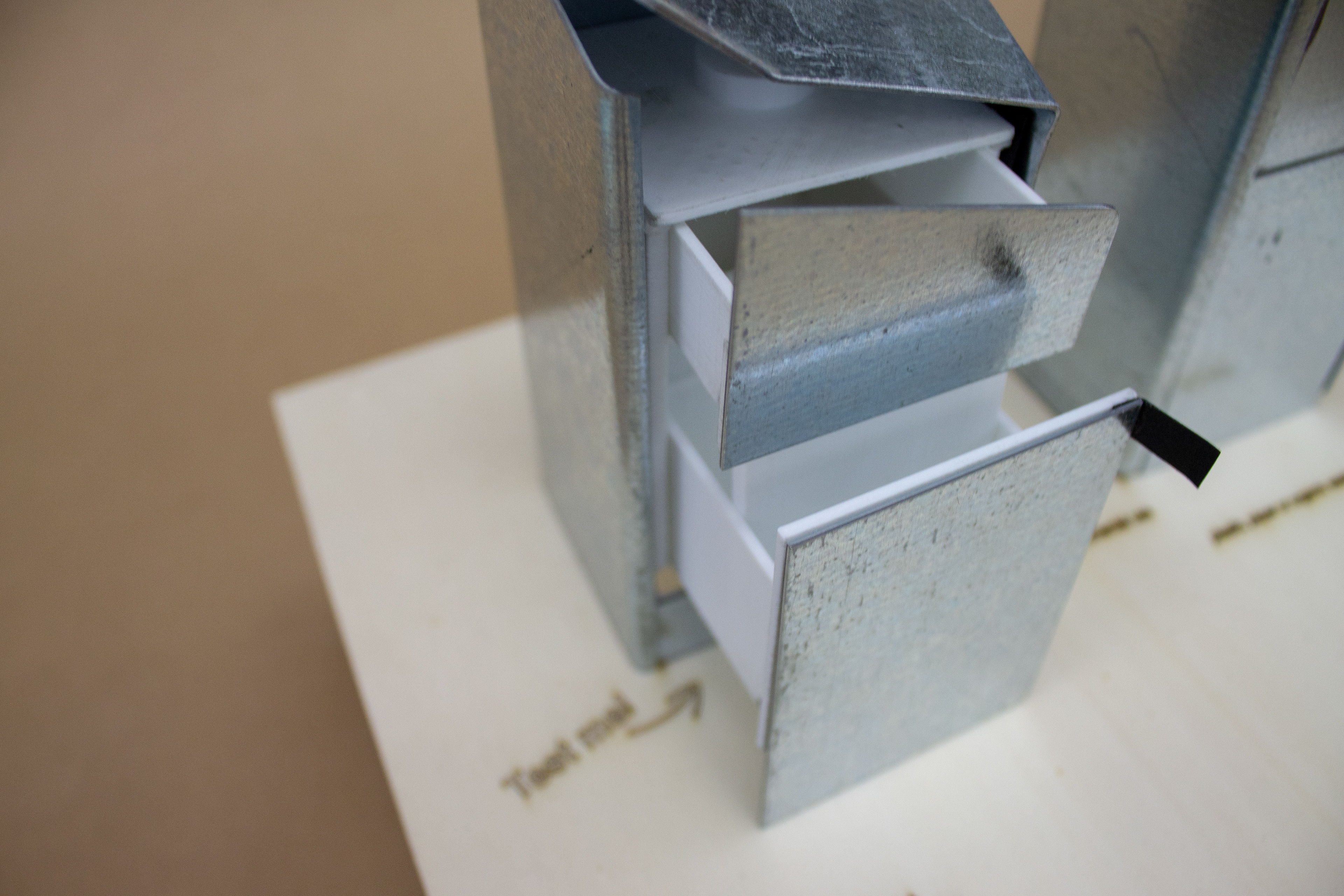

We created a special mechanism composed of two different drawers. You can use the top drawer, the bottom one or both in the same time if a big volume is required.

All services are provided with a mobile app.

Informations such as: user account, graphics, ENVAC contact details, inlets locations, recommendations and many more options.

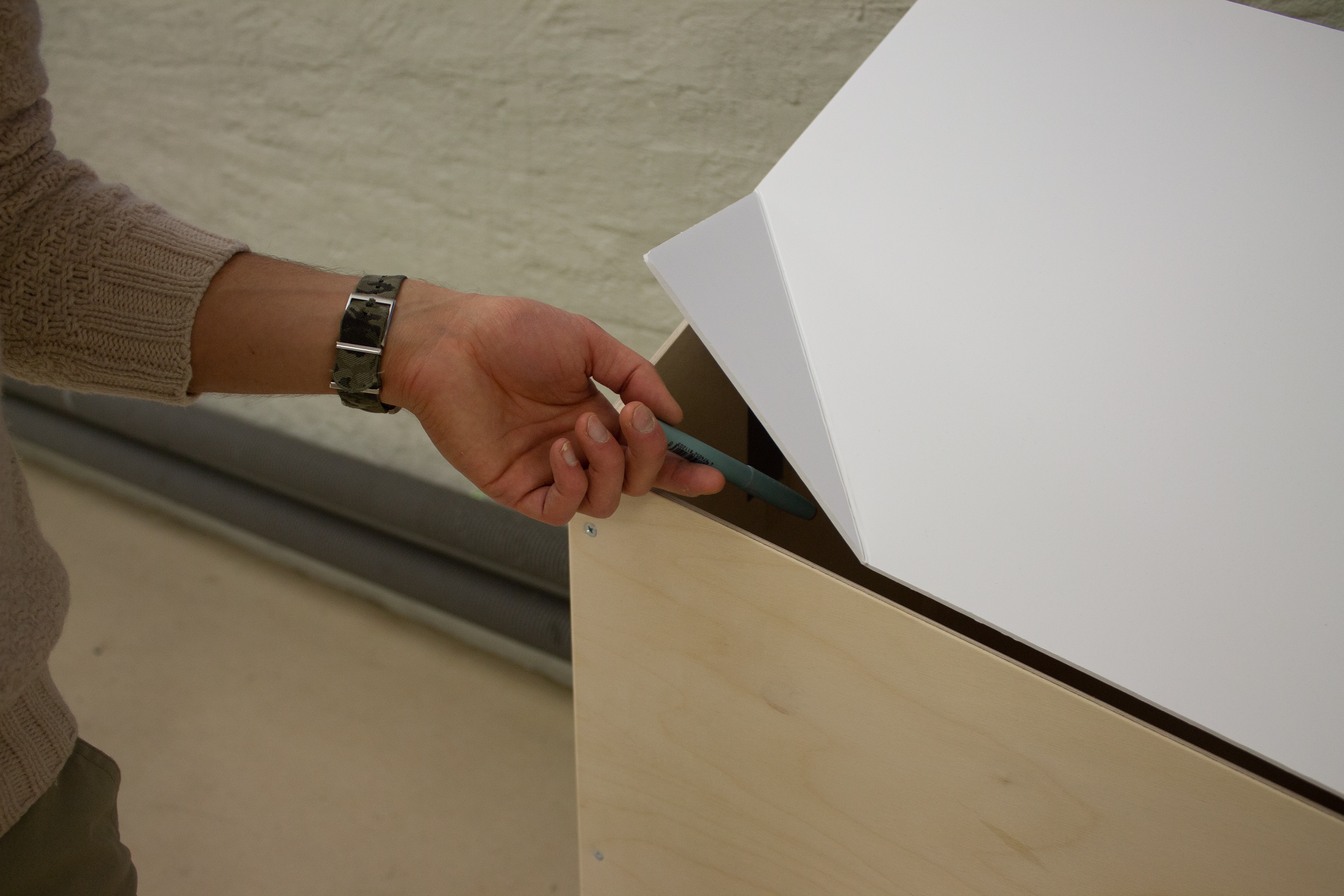

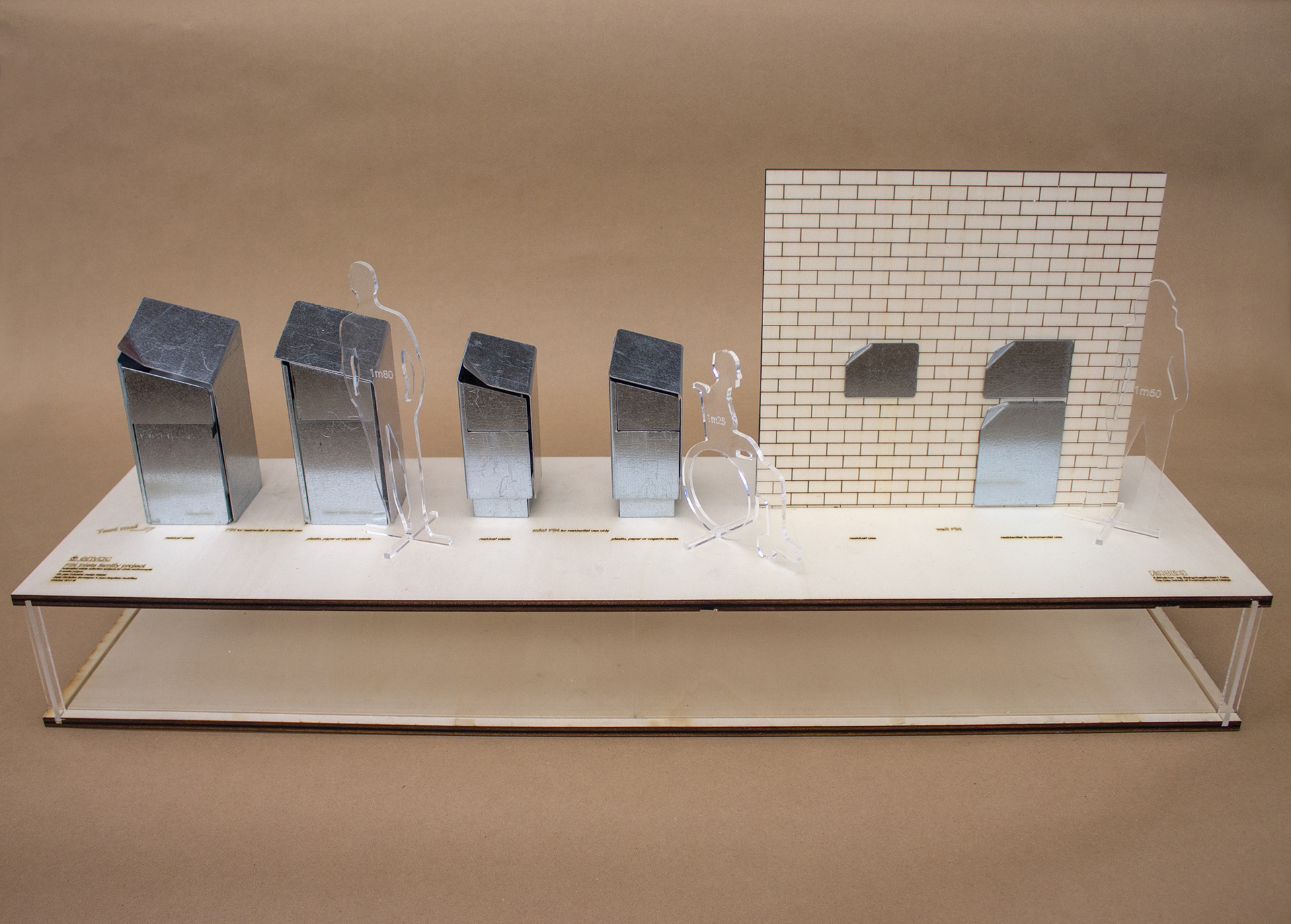

We made a scale-one model to verify the size and uses.

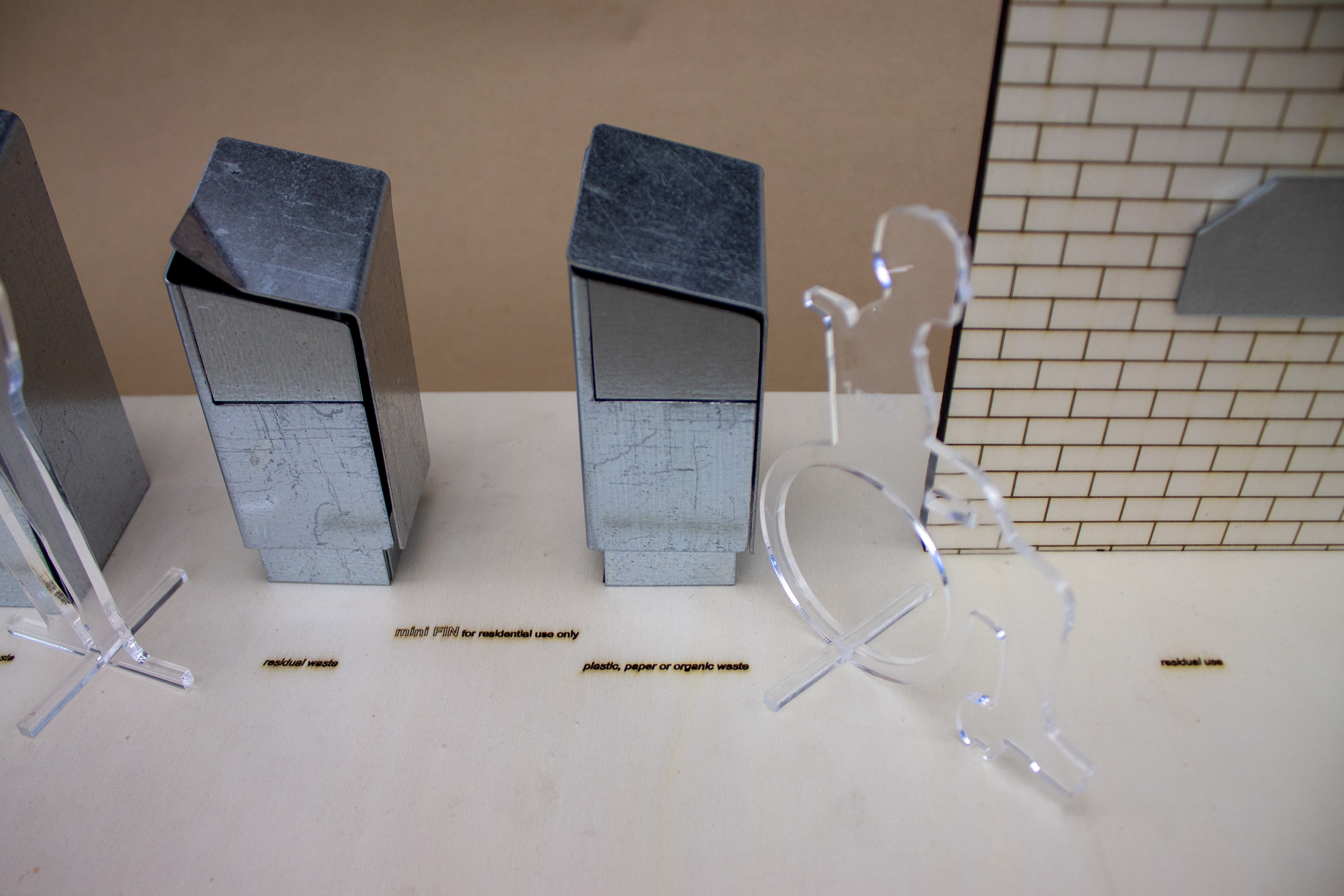

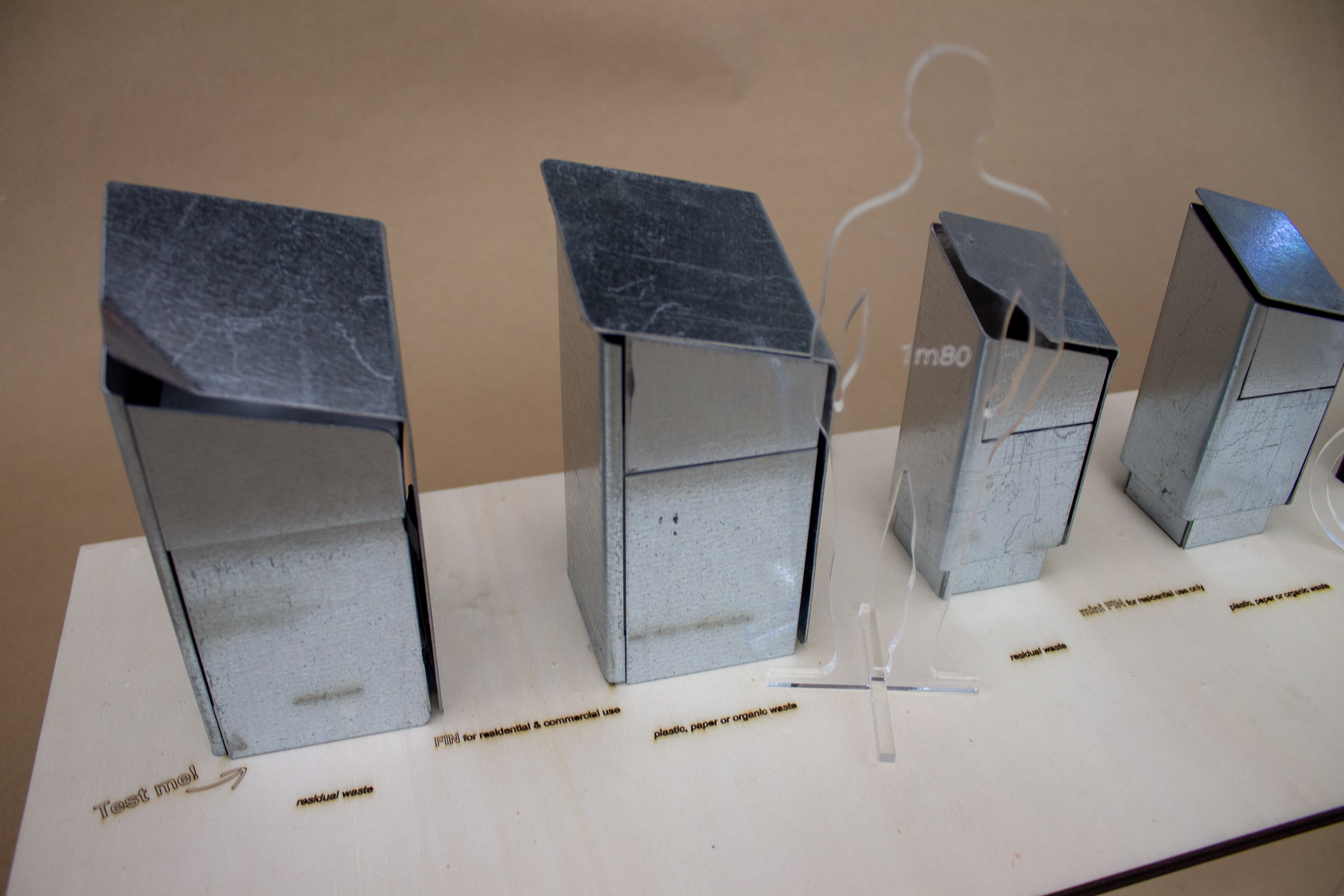

Then we made mockups with the final design using laser cutting, 3D printing and metal sheet bending.

We produced the residential, commercial and wall-mounted designs so we can understand the family identity.

One of them is functionally demonstrating the drawer system made with 3D printing.

We worked the dimensions as it is usable by the disabled.

A project made with Jens Christian Boxaspen for ENVAC.